Understanding Cartonization: A Complete Tutorial on Its Benefits and Implementation

Whatlearned about the company:

Paccurate

Paccurate is a parcel packing intelligence platform that optimizes packing efficiency for retailers, 3PLs, and carriers, reducing costs, minimizing waste, and improving sustainability in shipping operations.

impersonates as Supply Chain Efficiency Expert

creates article that:

Whatlearned about the company:

About the company

creates article that:

Results

Understanding Cartonization: A Complete Tutorial on Its Benefits and Implementation

Understanding Cartonization: A Complete Tutorial on Its Benefits and Implementation

Understanding Cartonization: A Complete Tutorial on Its Benefits and Implementation

Understanding Cartonization: A Complete Tutorial on Its Benefits and Implementation

In the fast-paced world of supply chains, efficiency isn't just a buzzword—it's a necessity. One critical area where this efficiency can make a substantial difference is in the packing process. Streamlining and optimizing packing processes can significantly cut costs, reduce delays, and ultimately, create a more agile and responsive supply chain.

The Importance of Optimizing the Packing Process

In today's competitive market, inefficiency comes with a hefty price tag. The packing process, often overlooked, is a key contributor to overall supply chain efficiency. When packing is inefficient, it can lead to increased costs, shipment delays, and customer dissatisfaction. According to recent studies, optimized packing processes can improve operational efficiency by up to 20%. This translates into faster turnaround times, cost savings, and enhanced customer satisfaction.

Imagine a scenario where goods are packed haphazardly, leading to wasted space and potential damage during transit. This not only increases shipping costs but also raises the risk of returns and replacements. Conversely, an optimized packing process ensures that every inch of space is utilized efficiently, reducing shipping costs and minimizing product damage.

Understanding the Current Packing Process

To streamline packing processes effectively, it's essential to understand the steps involved in traditional packing methods. Typically, the process includes picking items from inventory, assembling them in a packing area, wrapping and securing them, and finally, labeling and shipping.

However, several challenges can arise in this workflow:

- Inefficient Space Utilization: Poorly packed goods take up more space, leading to higher shipping costs.

- Time-Consuming Manual Processes: Manual packing is labor-intensive and prone to errors.

- Inadequate Training: Employees without proper training can inadvertently slow down the process.

These issues underscore the need for a more streamlined approach.

Streamlining the Packing Process

Innovative technologies and methodologies have emerged to revolutionize packing processes. For instance, automated packing machines can significantly reduce the time and effort required for packing. These machines use advanced algorithms to determine the most efficient way to pack items, maximizing space utilization and minimizing waste.

Consider the case of XYZ Logistics. They implemented an automated packing solution that reduced their packing time by 30% and cut down on material waste by 15%. Such case studies highlight the tangible benefits of adopting new technologies.

To successfully integrate these innovations, businesses must follow best practices such as:

- Conducting a Thorough Needs Assessment: Understand your specific requirements before investing in technology.

- Training Employees: Ensure that employees are well-versed in using new tools and technologies.

- Continuous Monitoring: Regularly review and adjust the packing process to maintain efficiency.

The Role of Employees in Optimizing Packing

While technology plays a crucial role, employees remain at the heart of any packing process. Engaging and training employees is vital for successful optimization. Well-trained staff can identify inefficiencies and suggest improvements, fostering a culture of continuous improvement.

Start by offering regular training sessions focused on new technologies and best practices. Encourage feedback and involve employees in decision-making processes. This not only boosts morale but also leads to practical insights that can further enhance efficiency.

Measuring the Impact of Streamlining Packing Processes

To gauge the success of your packing optimization efforts, it's essential to track key performance indicators (KPIs). Some critical KPIs include:

- Packing Time per Unit: Measure how long it takes to pack each item.

- Space Utilization: Assess how efficiently space is used within packages.

- Error Rate: Track the frequency of packing errors that lead to returns or damage.

Utilize tools like warehouse management systems (WMS) and data analytics platforms to collect and analyze these metrics. Regularly reviewing this data will help you identify areas for further improvement.

Overcoming Common Challenges in Packing Optimization

Implementing new processes and technologies often comes with challenges. One common hurdle is resistance to change. Employees accustomed to traditional methods may be hesitant to adopt new technologies. Address this by involving them early in the decision-making process and clearly communicating the benefits.

Technology adoption can also pose challenges. Ensure that the chosen solutions are user-friendly and provide adequate training and support. Additionally, manage the transition smoothly by rolling out new technologies in phases and continuously monitoring their impact.

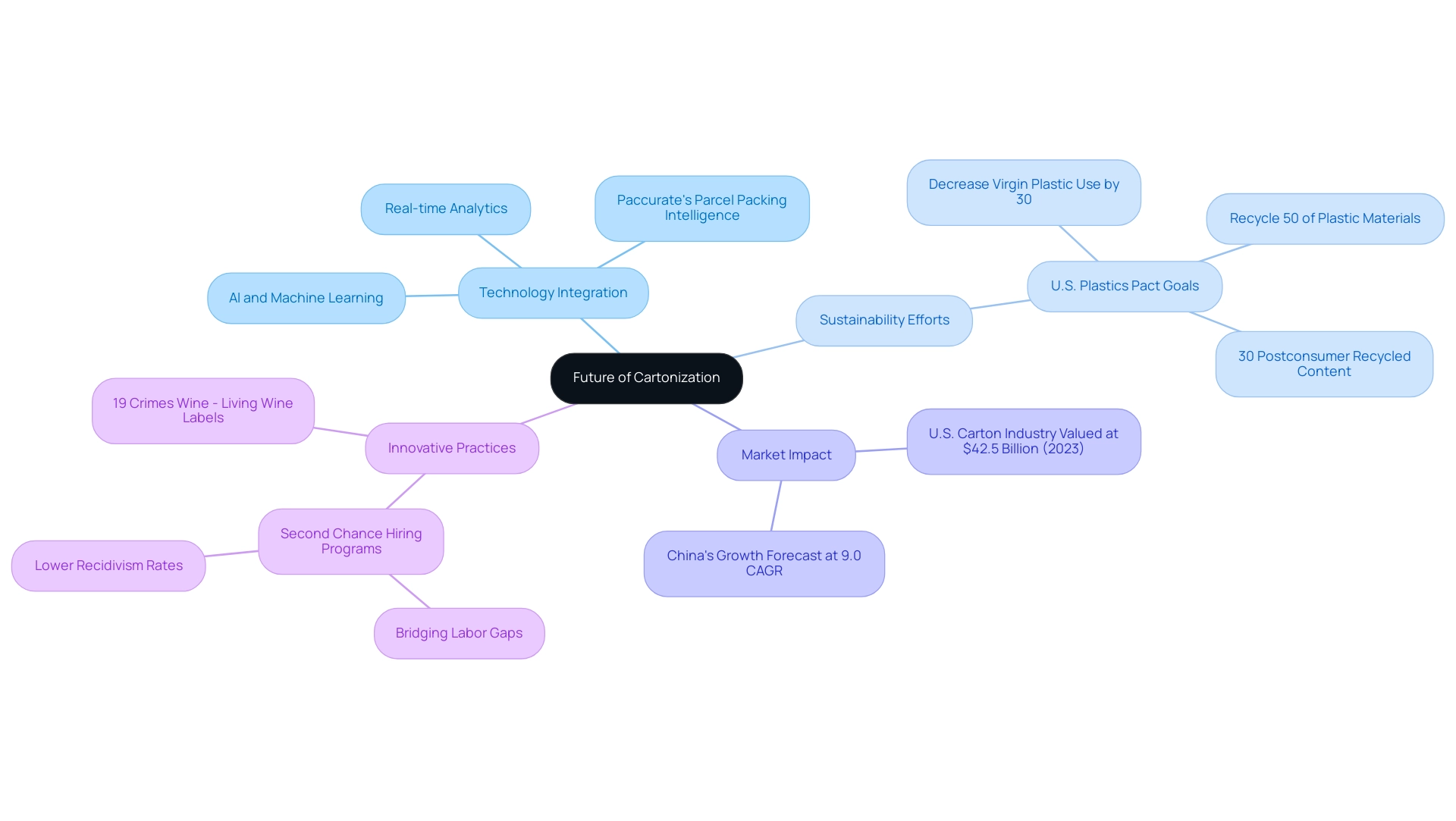

Looking to the Future: Innovations in Packing Optimization

The landscape of packing optimization is continually evolving. Emerging trends such as AI-powered packing algorithms, smart packaging materials, and IoT-enabled tracking systems promise to further enhance efficiency.

AI algorithms can predict the best packing configurations in real-time, while smart materials can adapt their shape to fit products better. IoT-enabled systems can provide real-time data on package conditions, ensuring that goods are transported safely and efficiently.

Staying abreast of these innovations and continuously seeking opportunities for improvement can help your business maintain a competitive edge.

Conclusion

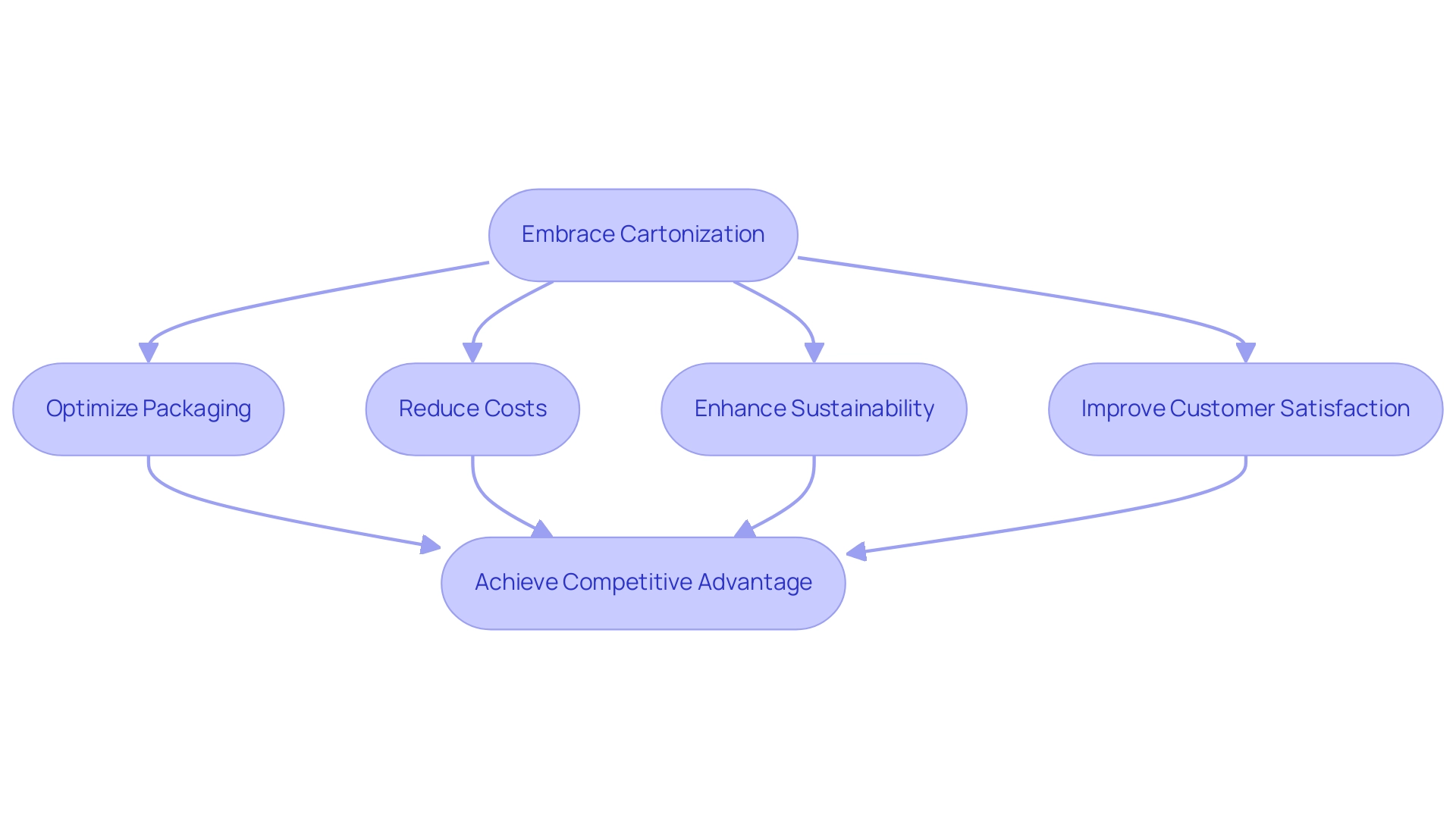

Optimizing the packing process is crucial for enhancing overall supply chain efficiency. By understanding current challenges, leveraging innovative technologies, engaging employees, and measuring impact, businesses can streamline their packing processes and realize significant benefits.

For businesses looking to start or continue their packing optimization journey, now is the time to act. Explore the latest technologies, involve your team, and continuously seek ways to improve. The path to a more efficient and responsive supply chain begins with optimizing your packing process.

Ready to take the next step? Start exploring opportunities to streamline your packing processes today and position your business for greater success.

Understanding Cartonization: A Complete Tutorial on Its Benefits and Implementation

Understanding Cartonization: A Complete Tutorial on Its Benefits and Implementation

Optimizing packing processes is crucial for enhancing efficiency and reducing costs. Streamlining the packing process involves implementing strategies and technologies to improve the speed, accuracy, and overall effectiveness of packing operations. By focusing on efficiency, companies can minimize errors, meet customer demands more effectively, and ultimately boost their bottom line. This introduction will explore key methods and tools that can be utilized to streamline the optimizing packing process, providing insights into how organizations can achieve greater efficiency and productivity in their packing operations.

Challenges in Traditional Packing Processes

In the fast-paced world of logistics and e-commerce, traditional packing processes face several challenges that hinder efficiency and productivity. Let's delve into the key issues that companies encounter with manual sorting and packing, space inefficiency, and time-consuming procedures.

Manual Sorting and Packing: The Burden of Manual Labor

One of the primary challenges in traditional packing processes is the heavy reliance on manual sorting and packing. This labor-intensive task not only increases the likelihood of errors but also slows down the entire packing operation. Workers must physically identify, sort, and pack items, leading to bottlenecks and inefficiencies in the process. Implementing automated sorting systems and packing solutions can significantly reduce errors, improve speed, and enhance overall efficiency.

Space Inefficiency: Maximizing Warehouse Utilization

Another significant challenge is space inefficiency within traditional packing processes. Without optimized packing strategies and tools, companies often waste valuable warehouse space. Inefficient packing not only limits the storage capacity but also increases the risk of damage during transit. By adopting smart warehouse layout designs, utilizing vertical storage solutions, and implementing efficient packing algorithms, businesses can maximize warehouse utilization, reduce storage costs, and ensure the safe transit of goods.

Time-Consuming Procedures: Streamlining Operations for Speed

Time-consuming procedures pose a significant obstacle in traditional packing processes. From manual data entry to multi-step packing workflows, the time required to fulfill orders increases significantly. As customer expectations for fast shipping continue to rise, companies must streamline their packing procedures to meet demand and remain competitive in the market. Introducing barcode scanning systems, automated order processing software, and real-time inventory management tools can help expedite packing processes, reduce lead times, and enhance customer satisfaction.

Addressing these challenges is crucial for companies looking to enhance their packing processes and improve overall operational efficiency. By leveraging technology, automation, and data-driven insights, businesses can overcome these obstacles and optimize their packing operations for success in the digital age. Embracing innovation and continuous improvement in packing processes will not only drive operational excellence but also position companies for sustained growth and competitiveness in the dynamic logistics landscape.

The need for efficient packing processes has never been more critical. With the rise of e-commerce and the increasing demand for quick order fulfillment, companies must adapt to overcome the challenges posed by traditional packing methods. Manual sorting and packing, although traditional, can lead to errors and delays, impacting customer satisfaction and operational costs. By transitioning to automated sorting systems and packing solutions, businesses can streamline their operations, reduce errors, and enhance overall efficiency.

Space inefficiency is another pressing issue that companies face in traditional packing processes. Inefficient use of warehouse space not only affects storage capacity but also impacts the organization's bottom line. Implementing smart warehouse layout designs, such as utilizing vertical storage solutions and optimizing packing algorithms, can help companies make the most of their available space, reduce storage costs, and ensure the safe handling of goods during transit.

Moreover, time-consuming procedures can hinder a company's ability to meet customer expectations for fast shipping. Speed and efficiency are paramount. By integrating barcode scanning systems, automated order processing software, and real-time inventory management tools, businesses can expedite their packing processes, minimize lead times, and ultimately improve customer satisfaction.

To stay ahead in the logistics and e-commerce industry, companies must continuously evaluate and enhance their packing processes. By embracing technological advancements, automation, and data-driven insights, businesses can not only address the challenges of traditional packing methods but also position themselves for success in the digital age. The key lies in adapting to change, optimizing operations, and prioritizing efficiency to meet the evolving demands of the modern consumer landscape.

Benefits of Streamlining Packing Processes

Optimizing packing processes is crucial for companies looking to stay competitive and meet customer demands. Streamlining packing processes can lead to a range of benefits that positively impact the overall efficiency and effectiveness of operations. Let's delve into some of the key advantages of streamlining packing processes:.

- Increased Productivity

- Efficient packing processes can significantly boost productivity by reducing the time required to prepare orders for shipment. By implementing streamlined packing procedures, companies can minimize bottlenecks, eliminate unnecessary steps, and ensure that orders are processed swiftly and accurately. This increase in productivity not only allows businesses to fulfill orders faster but also enables them to handle a higher volume of orders without compromising on quality.

- Cost Savings.

- Streamlining packing processes can result in cost savings for businesses in various ways. By optimizing the use of packaging materials and reducing waste, companies can lower their packaging costs. Additionally, improved efficiency in packing operations can lead to reduced labor costs and lower shipping expenses. Over time, these cost savings can have a significant impact on the bottom line, contributing to improved profitability and competitiveness in the market.

- Enhanced Customer Satisfaction.

- Efficient packing processes play a critical role in enhancing customer satisfaction. By streamlining packing operations, companies can ensure that orders are accurately picked, packed, and shipped in a timely manner. This not only reduces the likelihood of errors or delays but also helps in meeting customer expectations for fast and reliable order fulfillment. As a result, customers are more likely to receive their orders on time and in good condition, leading to higher levels of satisfaction and loyalty.

- Improved Inventory Management.

- Streamlining packing processes can also have a positive impact on inventory management. By optimizing packing procedures, companies can reduce the risk of stockouts, overstocking, and inventory errors. Efficient packing processes help in maintaining accurate inventory records, facilitating better demand forecasting, and ensuring that the right products are available when needed. This improved inventory management can lead to lower carrying costs, minimized stock obsolescence, and overall better control over inventory levels.

- Sustainability Benefits.

- Optimizing packing processes can contribute to sustainability efforts within a company. By reducing packaging waste, using eco-friendly materials, and implementing efficient packing practices, businesses can lower their environmental impact. Sustainable packing processes not only align with corporate social responsibility goals but also resonate with environmentally conscious consumers, enhancing brand reputation and attracting a more environmentally aware customer base.

The benefits of streamlining packing processes are multifaceted. From increased productivity and cost savings to enhanced customer satisfaction, improved inventory management, and sustainability benefits, optimizing packing operations can have a far-reaching positive impact on a business. By embracing efficient packing procedures, leveraging technology for automation, and prioritizing sustainability in packing practices, companies can not only streamline their operations but also position themselves as industry leaders committed to operational excellence and environmental stewardship.

Strategies for Optimizing Packing Efficiency

Optimizing packing efficiency is crucial for businesses to meet customer demands and stay competitive. By implementing the right strategies, companies can streamline their packing processes, reduce errors, and improve overall productivity. Let's explore some key strategies for optimizing packing efficiency:.

- Automation and Technology Integration

Incorporating automation and technology into the packing process can significantly improve efficiency. Automated systems can help in sorting, labeling, and packaging items quickly and accurately. By integrating technology such as barcode scanners and inventory management software, companies can reduce manual errors and speed up the packing process.

- Optimal Space Utilization

Efficient space utilization is essential for maximizing packing efficiency. By organizing the packing area effectively and utilizing storage space wisely, companies can reduce the time spent searching for items and moving inventory around. Implementing shelving systems, storage bins, and clear labeling can help in optimizing space and improving overall efficiency.

- Standardized Packing Procedures

Establishing standardized packing procedures is key to ensuring consistency and efficiency in the packing process. By creating clear guidelines for packing items, companies can reduce errors, minimize packing time, and enhance overall quality control. Training employees on standardized procedures and regularly reviewing and updating them can help in maintaining efficiency levels.

- Quality Control Measures

In addition to standardized procedures, implementing robust quality control measures is essential for optimizing packing efficiency. Conducting regular quality checks during the packing process can help identify and rectify errors early on, ensuring that only high-quality products are shipped to customers. Quality control measures also contribute to building a positive brand reputation and increasing customer satisfaction.

- Employee Training and Engagement

Investing in employee training and fostering a culture of engagement can significantly impact packing efficiency. Well-trained and motivated employees are more likely to perform packing tasks accurately and efficiently. Providing ongoing training opportunities, recognizing employee contributions, and encouraging feedback can boost morale and productivity within the packing team.

By implementing these comprehensive strategies for optimizing packing efficiency, businesses can enhance their operations, meet customer expectations, and achieve greater success in today's competitive market. Embracing automation, maximizing space utilization, standardizing procedures, focusing on quality control, and prioritizing employee training are key pillars in building a highly efficient packing operation.

Case Studies on Successful Packing Process Optimization

Optimizing the packing process is crucial for efficiency and cost-effectiveness. Let's delve into two case studies that showcase successful packing process optimization strategies.

Company A: Implementing Automated Packing Solutions

Company A, a leading e-commerce retailer, was facing challenges with manual packing processes leading to errors, delays, and increased costs. To address these issues, the company decided to implement automated packing solutions. By integrating automated packing machines and software, Company A was able to significantly improve packing accuracy, reduce packing time, and streamline the entire process. This not only enhanced operational efficiency but also improved customer satisfaction due to faster order processing and reduced errors.

Company B: Reducing Packing Time through Process Reengineering

Company B, a global manufacturer, was struggling with lengthy packing times that were impacting order fulfillment and delivery schedules. To tackle this issue, the company opted for process reengineering focused on optimizing the packing workflow. By reorganizing packing stations, standardizing packing procedures, and providing training to employees, Company B successfully reduced packing time by 30%. This optimization not only increased productivity but also allowed the company to handle a higher volume of orders without compromising on quality.

These case studies highlight the importance of packing process optimization in enhancing operational efficiency, reducing costs, and improving customer satisfaction. By leveraging automation, reengineering, and innovative solutions, companies can transform their packing operations and stay competitive in today's fast-paced business environment.

Additional Insights:

- Importance of Technology Integration: Discuss how integrating technology such as IoT sensors for inventory management or AI for predictive packing can further enhance the packing process efficiency.

- Sustainability in Packing: Explore how sustainable packing materials and eco-friendly practices can align with optimization efforts, appealing to environmentally conscious consumers.

- Real-time Tracking and Visibility: Highlight the benefits of real-time tracking systems in packing operations, enabling transparency and accountability throughout the supply chain.

- Employee Training and Engagement: Emphasize the role of continuous training programs and employee engagement initiatives in sustaining optimized packing processes and fostering a culture of efficiency.

By continuously evolving and adapting packing processes to meet changing market demands and technological advancements, businesses can not only achieve operational excellence but also drive innovation and customer loyalty.

Future Trends in Packing Process Optimization

Businesses are constantly seeking ways to optimize their packing processes to improve efficiency and reduce costs. With advancements in technology and a growing focus on sustainability, the future of packing process optimization looks promising. Let's delve into two key trends that are shaping the future of packing processes:.

- Leveraging AI and Machine Learning in Packing

Artificial Intelligence (AI) and Machine Learning are revolutionizing the packing industry. These technologies can analyze vast amounts of data to optimize packing processes, predict demand patterns, and even automate packaging tasks. By leveraging AI and Machine Learning, businesses can enhance their efficiency, reduce errors, and meet customer demands more effectively. Moreover, AI-powered systems can provide real-time insights, enabling companies to make data-driven decisions and streamline their packing operations further.

- Embracing Sustainable Packaging Solutions

As environmental concerns continue to rise, sustainable packaging solutions are becoming increasingly important. Businesses are not only focusing on the efficiency of their packing processes but also on the environmental impact of their packaging materials. They are exploring eco-friendly materials, biodegradable packaging options, and innovative designs to reduce their carbon footprint. By adopting sustainable packaging solutions, companies can not only contribute to environmental conservation but also appeal to environmentally conscious consumers. Additionally, sustainable packaging can enhance brand reputation and customer loyalty, as consumers are increasingly valuing products that are packaged in an environmentally friendly manner.

The future of packing process optimization lies in embracing a holistic approach that combines technology, sustainability, and innovation. By incorporating AI and Machine Learning into packing processes and adopting sustainable packaging solutions, businesses can stay ahead of the curve and drive success in a rapidly evolving market. It is essential for companies to continuously evaluate and update their packing strategies to align with these future trends and remain competitive in the dynamic business landscape.

- Automation in Packaging

Another significant trend in packing process optimization is the increasing adoption of automation. Automated packaging systems can significantly improve efficiency, reduce labor costs, and minimize errors in the packing process. These systems can handle repetitive tasks with precision and speed, allowing businesses to streamline their operations and meet growing demands effectively. By integrating automation into their packing processes, companies can achieve higher productivity levels and ensure consistent quality in their packaging.

- Personalization in Packaging

Personalized packaging is gaining traction as a way to enhance customer engagement and brand loyalty. Businesses are leveraging technology to create customized packaging solutions that cater to individual customer preferences. From personalized messages to unique packaging designs, companies are using personalization to create memorable unboxing experiences for their customers. By offering personalized packaging options, businesses can differentiate themselves in the market, strengthen customer relationships, and increase brand recognition.

The future of packing process optimization is evolving rapidly, driven by advancements in technology, a focus on sustainability, and the need for innovation. By embracing AI and Machine Learning, adopting sustainable packaging solutions, integrating automation, and incorporating personalization in packaging, businesses can position themselves for success in a competitive market landscape. It is crucial for companies to stay informed about these emerging trends, adapt their packing processes accordingly, and strive for continuous improvement to meet the changing needs and expectations of consumers.

Conclusion

Streamlining and optimizing the packing process is crucial for enhancing efficiency and productivity in any operation. By implementing efficient packing strategies, utilizing appropriate tools and technology, and continuously seeking ways to improve the process, businesses can reduce costs, minimize errors, and ultimately deliver better results to their customers. Embracing a culture of continuous improvement and innovation in packing operations can lead to significant benefits and competitive advantages in today's fast-paced business environment.

Search engines index & rank higher Tely’s expert-level articles

For each article we use at least 30 sources to add cases, report data, quotes and infographics.

Tely AI uses real world information to position your company as an industry expert

Tely AI generates infographics to capture visitors attention

Tely inserts quotes and expert opinions of niche industry leaders

Tely paraphrases all texts to sound human and bypass AI content detectors

As we reach 2023, a GPT-4-based model has solved 84.3% of problems, nearing the human baseline of 90%. As we continue to push AI's limits in mathematics, we are compelled to create new benchmarks to highlight the differences and advantages between human and AI problem-solving.

In a test involving 30 problems from the International Mathematical Olympiad, AlphaGeometry was able to solve 25. This performance significantly surpasses previous methods, which could only solve 10 problems.

The ability of AI to process and analyze massive data sets has the potential to revolutionize the methodologies and problem-solving approaches used in mathematics.

“Machine learning tools are very good at recognizing patterns and analyzing very complex problems.”

Consider the “ai math” problem, a complex mathematical challenge that has been made more manageable through AI's capabilities. This not only saves considerable time but also opens new avenues for innovative mathematical research.

.webp)